-

Rubber Kneader MachineA Rubber Kneader is a type of industrial equipment used in the rubber and plastics industries to mix...

Rubber Kneader MachineA Rubber Kneader is a type of industrial equipment used in the rubber and plastics industries to mix... -

Rubber Banbury MachineIn the field of modern rubber and plastic processing, efficient, energy-saving, and environmentally ...

Rubber Banbury MachineIn the field of modern rubber and plastic processing, efficient, energy-saving, and environmentally ... -

Rubber Open Mixing MillThe open rubber mixing mill has two horizontally arranged rollers, and the process of rubber (or pla...

Rubber Open Mixing MillThe open rubber mixing mill has two horizontally arranged rollers, and the process of rubber (or pla... -

Twin Screw Feeding Extruder MachineIn the rubber processing industry, the mixing process directly affects the quality of the finished p...

Twin Screw Feeding Extruder MachineIn the rubber processing industry, the mixing process directly affects the quality of the finished p... -

2 Rolls Rubber Calender MachineIt is mainly used for calendering rubber products such as tyres, conveyor belts, rubber sheets, etc.

2 Rolls Rubber Calender MachineIt is mainly used for calendering rubber products such as tyres, conveyor belts, rubber sheets, etc. -

3 Rolls Rubber Calender MachineIt is mainly used for one-face, once-continuous coating of rubber sheets made from fiber cord, canva...

3 Rolls Rubber Calender MachineIt is mainly used for one-face, once-continuous coating of rubber sheets made from fiber cord, canva... -

4 Rolls Rubber Calender MachineIt is mainly used for one-face and double face, once continuous coating rubber sheet of fiber cord, ...

4 Rolls Rubber Calender MachineIt is mainly used for one-face and double face, once continuous coating rubber sheet of fiber cord, ... -

5/6 Roller Plastic Calender MachineIn the modern plastic processing industry, achieving consistent thickness, high surface quality, and...

5/6 Roller Plastic Calender MachineIn the modern plastic processing industry, achieving consistent thickness, high surface quality, and... -

PVC Plastic Soft Film Calendering MachineThis production line is used to produce farm film, package color film,transparent film ,flex banner ...

PVC Plastic Soft Film Calendering MachineThis production line is used to produce farm film, package color film,transparent film ,flex banner ... -

PVC Rigid Sheet Calendering LineThis production line is used to produce all kinds of transparent,semi-transparent, and high filling ...

PVC Rigid Sheet Calendering LineThis production line is used to produce all kinds of transparent,semi-transparent, and high filling ... -

Hot Feed ExtruderIn the rubber processing industry, hot feed extrusion remains a vital technology for producing semi-...

Hot Feed ExtruderIn the rubber processing industry, hot feed extrusion remains a vital technology for producing semi-... -

Cold Feed ExtruderIn today’s rubber manufacturing industry, where consistency, automation, and energy efficiency are k...

Cold Feed ExtruderIn today’s rubber manufacturing industry, where consistency, automation, and energy efficiency are k... -

Microwave Hot Air Curing LineIn the rubber manufacturing industry, vulcanization is a critical process that determines the final ...

Microwave Hot Air Curing LineIn the rubber manufacturing industry, vulcanization is a critical process that determines the final ... -

Vulcanizing RollerIn the rubber industry, the vulcanization process is the key link to determine the performance of th...

Vulcanizing RollerIn the rubber industry, the vulcanization process is the key link to determine the performance of th... -

High Temperature Oil ControllerIn many industrial fields such as rubber, plastics, chemicals, die-casting, composite materials, etc...

High Temperature Oil ControllerIn many industrial fields such as rubber, plastics, chemicals, die-casting, composite materials, etc...

Rubber Products

Our equipment solutions in the rubber products field, characterized by "continuous molding, high-precision control, and multi-category compatibility," can deeply cover the full-scenario production of plate-shaped products and special-shaped/strip products. They are highly adaptable to both basic industrial parts and end consumer goods. The detailed expansion is as follows:

I. Plate-shaped Rubber Products: Focusing on the Production of "Large-area, High Uniformity, and Functional Composite"

1. Industrial and Special Rubber Sheets

- Application Scenarios: Including chemical anti-corrosion rubber sheets (such as anti-corrosion layers for floors in electroplating workshops), food-grade wear-resistant rubber sheets (such as anti-slip pads for operating tables in slaughterhouses), and high-temperature-resistant silicone rubber sheets (such as liners for ovens in electronics factories).

- Technical Adaptability: Through high-precision sheeting of raw materials like natural rubber, nitrile rubber, and silicone rubber by calenders (thickness range 0.5-50mm, deviation ≤0.03mm), combined with single-sided/double-sided continuous rubberizing technology for textiles (canvas, fiberglass cloth), the tear resistance of rubber sheets can be enhanced (tensile strength increased by over 30%). For example, chemical anti-corrosion rubber sheets require an acid and alkali-resistant rubber layer attached to the base layer. The equipment ensures instant bonding between the rubber layer and the base material without bubbles by synchronously controlling the temperature (120-180℃) and pressure of the calender rolls, avoiding delamination caused by chemical penetration.

- Core Advantages: Compared with traditional molding processes, continuous calendering can realize one-time molding of rubber sheets over 100 meters long, significantly reducing splicing loss (material utilization rate increased from 70% to over 95%).

2. Thin Conveyor Belts and Printing Blankets

- Thin Conveyor Belts: Suitable for light material conveying (such as cosmetic production lines and pharmaceutical packaging lines), adopting a "polyester cord fabric + rubber layer" composite structure. The equipment realizes instant curing of the cord fabric and rubber material through continuous rubberizing technology, with the rubber layer thickness controlled at 0.3-1mm, ensuring the conveyor belt is thin yet tough (tensile strength up to 15MPa). Its surface smoothness (Ra ≤0.8μm) meets food-grade hygiene standards (compliant with FDA 21 CFR 177.2600).

- Printing Blankets: As core consumables for printing presses, they need to have high elasticity and dimensional stability. The equipment performs multi-layer composite calendering of nitrile rubber and nylon base cloth through calenders, precisely controlling the thickness ratio of each layer (rubber layer: base cloth = 1:2), ensuring the blanket does not stretch or deform during high-speed printing (30,000 sheets/hour), suitable for high-precision printing of books and packaging.

3. Waterproof Materials and Rubber-plastic Flooring

- Waterproof Materials: Such as roof waterproofing membranes (composite of rubber and polyester non-woven fabric) and tunnel water-stop plates. The equipment realizes one-time compounding of rubber layers (such as EPDM rubber) and reinforcing cloth through double-sided continuous rubberizing technology. The rubber layer density reaches over 1.2g/cm³, ensuring water impermeability (no leakage under 0.3MPa pressure for 30 minutes), and its low-temperature flexibility (-30℃ without cracks) is suitable for cold regions in northern China.

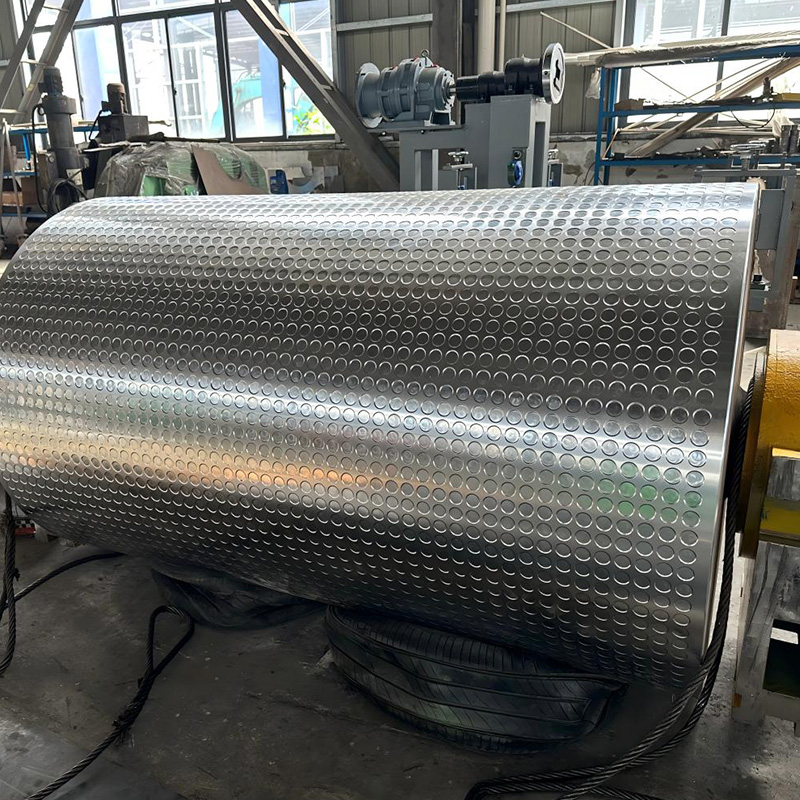

- Rubber-plastic Flooring: Wear-resistant and anti-slip flooring used in shopping malls, hospitals, etc., adopting calendered compounding of "PVC rubber material + fiberglass felt." The equipment can simultaneously complete rubber material coloring, embossing (such as wood grain, marble grain imitation), and base material bonding, with a production speed of 20 meters/minute. By controlling the calendering temperature (160-180℃), the thermal shrinkage rate of the flooring is ensured to be ≤0.5%, avoiding arching after installation.

4. Liners and Functional Plates

- Industrial Liners: Such as anti-corrosion liners for storage tanks (butyl rubber sheets) and wear-resistant liners for centrifuge drums (neoprene rubber sheets). The high-precision thickness control of calenders (deviation ≤0.02mm) ensures perfect bonding between the liner and the inner wall of the equipment, reducing gaps for medium penetration; the continuous production mode can meet the demand for integral liners of large storage tanks (with a diameter of over 10 meters), avoiding corrosion risks caused by splicing gaps.

- Sound Insulation and Shock Absorption Plates: Rubber sound insulation plates (composite of rubber and sound-absorbing cotton) used in buildings and automobiles. The equipment realizes close bonding between the rubber layer and sound-absorbing materials through rubberizing technology, and the uniformity of the rubber layer ensures stable sound insulation (≥25dB), suitable for noise reduction in residential elevator shafts and automobile engine compartments.

II. Special-shaped/Strip Rubber Products: Overcoming Production Difficulties of "Seamless, High Precision, and Complex Structure"

1. Seamless Circular Belts and Transmission Belts

- Application Scenarios: Food conveying circular belts (such as biscuit production lines), synchronous belts for textile machinery, and base belts for sander sanding belts.

- Technical Breakthrough: Traditional circular belts are mostly spliced with joints, which are prone to breakage during high-speed operation. Our equipment realizes one-time molding of seamless circular belts through a "continuous extrusion-calendering-vulcanization integration" process: first, the rubber material and cord fabric base layer are calendered and compounded, then continuously vulcanized through a circular mold, ensuring the perimeter deviation of the belt body is ≤1mm, and the joint strength is consistent with the main body (breaking strength ≥18MPa), suitable for industrial production lines operating continuously for 24 hours.

2. Rubber Sealing Strips and Profiles

- Sealing Strips: Including automotive door and window sealing strips (EPDM material) and container door frame sealing strips (composite of EPDM and foam rubber). The equipment can produce sealing strips with complex cross-sections (such as structures with flocking layers and steel core skeletons) through "multi-roll calendering + extrusion compounding" technology, with dimensional accuracy (cross-sectional deviation ≤0.1mm) ensuring a perfect fit with the assembly groove, and flocking adhesion (≥5N/25mm) avoiding falling off during assembly.

- Profiles: Such as cable protective sleeves (neoprene) and fitness equipment handle sleeves (foam rubber). The equipment supports co-extrusion calendering of multiple rubber materials (such as hard rubber + soft rubber composite), enabling one-time molding of complex cross-sections like "T-type," "L-type," and "hollow type," with production efficiency increased by 50% compared to traditional molding, and online inspection systems to eliminate products with dimensional deviations.

3. Rubber Hoses and Fluid Conveying Accessories

- Industrial Hoses: Such as oil-resistant hoses (nitrile rubber inner layer + canvas reinforcement layer) and food-grade silicone hoses (used for dairy product conveying). The equipment adopts a "continuous process of inner rubber calendering - reinforcement layer braiding - outer rubber bonding," ensuring the inner diameter tolerance of the hose (≤0.2mm) and pressure resistance (working pressure 1-10MPa). Moreover, the production of silicone hoses can meet USP Class VI medical certification, suitable for clean conveying in pharmaceutical and food industries.

- High-pressure Hose Joints: The sealing rubber rings for hose joints are produced by calenders, with high-precision dimensional control (diameter deviation ≤0.05mm) ensuring a tight fit with metal joints, avoiding high-pressure fluid leakage (such as hoses in hydraulic systems).

4. Water-stop Belts and Engineering Seals

- Water-stop Belts: Rubber water-stop belts (natural rubber + cord fabric reinforcement) used in water conservancy projects (such as dams and tunnels). The equipment embeds cord fabric into the rubber belt body through continuous rubberizing technology, forming water-stop structures such as "central holes" and "ribs." The peel strength between the rubber layer and the fabric layer is ≥3kN/m, ensuring no delamination under water pressure, suitable for high water pressure scenarios with a water head of over 100 meters.

- Engineering Seals: Such as building expansion joint sealing strips (neoprene) and bridge bearing dust covers (EPDM rubber). The calendering process can realize one-time molding of fine structures such as "lips" and "grooves" of seals, with dimensional stability (dimensional change rate ≤3% after thermal aging) meeting the requirements of long-term outdoor use.

III. Technical Empowerment: Creating Three Core Values for the Rubber Products Industry

- Efficiency Revolution: The continuous production mode increases the daily output of plate-shaped products to 2-3 times that of traditional processes (e.g., rubber-plastic flooring can reach 10,000㎡ per day), and the mold change time for special-shaped products is shortened to within 30 minutes, adapting to the demand for "multi-variety, large-batch" orders.

- Quality Upgrade: High-precision calendering (thickness deviation ≤0.02mm) and rubberizing (rubber layer uniformity ≥98%) ensure consistent product performance. For example, the printing resistance of printing blankets increases from 300,000 sheets to over 500,000 sheets, and the service life of water-stop belts is extended to more than 30 years.

- Cost Optimization: The material utilization rate is increased from 60%-70% in traditional processes to over 90%, reducing rubber material waste; integrated production reduces intermediate links (such as secondary bonding and trimming), lowering labor costs by 40%.

By covering the production of full-category rubber products including "plate-shaped + special-shaped," our equipment can not only meet the precision manufacturing of industrial-grade high-demand parts but also support large-scale supply of consumer goods, becoming a core equipment support for rubber product enterprises to transform from "processing OEM" to "high-value-added product research and development."

English

English 中文简体

中文简体 русский

русский