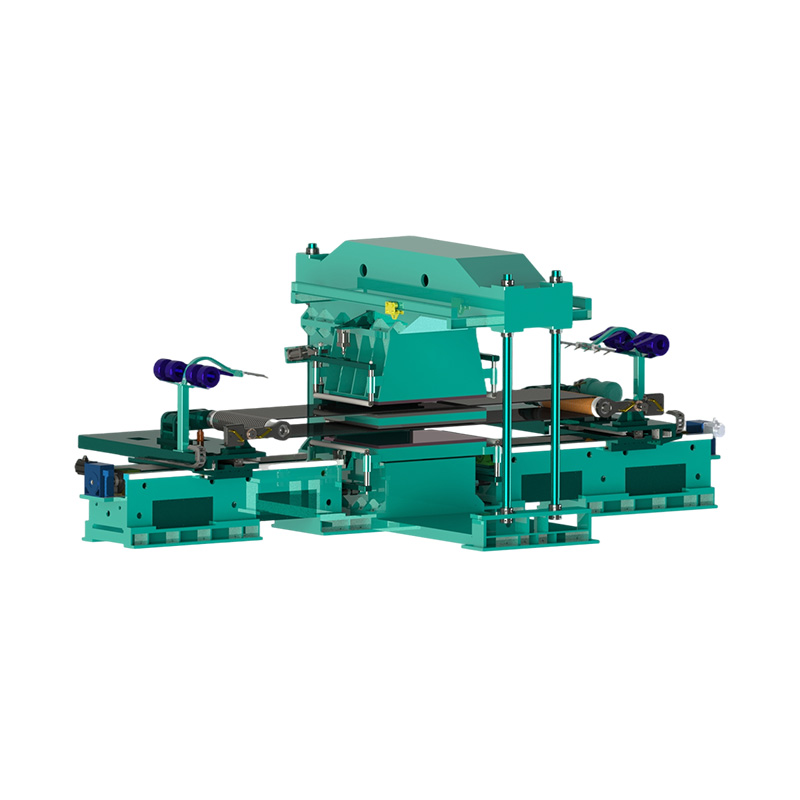

What is a V-belt vulcanizing machine?

V-belt vulcanizing machine is a special equipment for the production of V-belt (V-type conveyor belt). This machine processes raw materials into V-belt core or strip blank through a series of process steps, such as cord opening, dipping, laminating, cutting, etc.

Specifically, a V-belt vulcanizing machine usually includes a forming drum, a drawing drum, an extrusion device, a cloth roller, a cloth storage rack, and feeding device, and other components. In the manufacturing process, these parts work together to first place the annular compression layer of film on the forming drum and the stretching drum, and tension it. Then, the feeding device draws the curtain fabric, sends it to the cloth storage rack for storage, and then supplies the cloth to the forming drum through the cloth roller, and wraps the curtain fabric on the compressed layer film. Finally, by pressing the roller of the extrusion device against the forming drum, the formed broadband blank is extruded and cut into a single V-belt core.

In addition, some V-belt vulcanizing machines also use the double drum group forming method, which can produce the wire V-belt within the specific perimeter range, and can be completed separately by guiding the wire rope, dipping glue, group pressing the base glue, group cutting strip, and other processes.

V-belt vulcanizing machine performance

The performance of the V-belt vulcanizing machine is mainly reflected in the following aspects:

1, production efficiency: The V-belt vulcanizing machine adopts an automatic and continuous production mode, which can cut multiple strip cores at one time, such as the intelligent rubber V-belt forming slitting machine can cut 20 B-type belt cores at a time, which greatly improves production efficiency.

2, product accuracy: The V-belt vulcanizing machine is equipped with high-precision cutting, laminating, and grinding devices to ensure that the V-belt core produced has an accurate size and shape to meet the needs of various industrial applications.

3, Stability and reliability: The V-belt vulcanizing machine considers stability and reliability in structural design, adopts high-quality materials and advanced manufacturing processes to ensure that the equipment can maintain a stable working state during long-term operation and reduce the failure rate.

4, easy operation: The V-belt vulcanizing machine has a humanized operation interface and control system, so that the operator can easily set parameters, monitor the production process, reduce the difficulty of operation, and improve work efficiency.

5, energy saving and environmental protection: with the development of technology, the V-belt vulcanizing machine has also made significant progress in energy saving and environmental protection, such as the use of energy-saving motors, optimizing production processes, reducing energy consumption and emissions, in line with the requirements of sustainable development.

Application range of the V-belt vulcanizing machine

The V-belt vulcanizing machine has a wide range of applications. Because the V-belt (V-shaped tape or triangle belt) has the characteristics of simple installation, small footprint, high transmission efficiency, and low noise, it is widely used in many fields.

Specifically, V-belt is mainly used in machinery, metallurgy, electric power, mining, chemical, building material,s and ports, and other fields. In these fields, the V-belt, as an important mechanical power transmission component, plays a key role in transmitting force and goods transportation. In addition, the V-belt is also widely used in agricultural machinery, construction machinery, automobiles, trains, and other fields that need transmission and transmission.

The V-belt vulcanizing machine is the special equipment used to produce this V-belt, so its range of use is closely related to the application field of the V-belt. By using a V-belt vulcanizing machine, V-belt products that meet various specifications and requirements can be efficiently produced to meet the needs of different industries.

V-belt vulcanizing machine manufacturer selected.

When choosing a V-belt vulcanizing machine manufacturer, it is recommended to consider the following aspects:

1, brand and strength: choosing suppliers with well-known brands and strong strength usually means a higher level of technology and more reliable product quality. Such suppliers usually have many years of industry experience and are able to provide more comprehensive solutions and quality after-sales service.

2, product performance and quality: pay attention to the performance parameters and quality indicators of the V-belt vulcanizing machine, such as production efficiency, accuracy, stability, and so on. At the same time, understand the material selection of the product, process manufacturing, and other aspects of information to ensure that the purchased equipment can meet the actual production needs.

3, after-sales service and support: Good after-sales service is a factor that can not be ignored when choosing suppliers. Understanding the supplier's after-sales service content, response speed, and problem-solving ability helps to ensure timely and effective support when problems are encountered during use.

4, price and cost performance: Price is an important factor to consider when choosing suppliers. However, we should not only pay attention to the price, but also consider the factors such as product performance, quality, and after-sales service to choose cost-effective suppliers.

5, customer evaluation and word of mouth: understand the evaluation and word of mouth of other customers on suppliers, to help understand the actual situation of suppliers more comprehensively. You can obtain relevant information by consulting industry reports, consulting industry insiders, or visiting suppliers' official websites.

V-belt vulcanizing machine structure features

The structural characteristics of the -belt vulcanizing machine are mainly reflected in the following aspects:

1, modular design: V-belt vulcanizing machine usually adopts modular design, the various functional modules are divided, easy to assemble, repair, and replace. This design makes the structure of the equipment more compact, but also improves the reliability and maintainability of the equipment.

2, high-precision machining parts: The key parts in the forming machine, such as forming drums, stretching drums, cloth rollers, etc., are processed with high precision to ensure the molding accuracy and dimensional stability of the V-belt core. This high-precision processing not only improves the quality of the product but also extends the service life of the equipment.

3, automatic control system: The V-belt vulcanizing machine is equipped with an advanced automatic control system, which can realize the automatic feeding, automatic forming, automatic cutting, and other functions of the equipment. Through the touch screen or computer interface, the operator can easily set parameters, monitor the production process, and obtain production data in real time, improving production efficiency and operation convenience.

4, safety protection measures: the equipment is fully considered in the design of safety factors, the use of protective covers, safety doors, and other safety protection measures to prevent operators from being injured in the production process. At the same time, the equipment is also equipped with safety devices such as an emergency stop button to ensure that it can be stopped quickly in emergencies to avoid accidents.

5, environmental protection and energy saving design: V-belt vulcanizing machine pays attention to environmental protection and energy saving in design, the use of low-energy motor, inverter, and other electrical components to reduce energy consumption. At the same time, the noise, exhaust gas, and other pollutants generated by the equipment in the production process are also effectively controlled, which meets the requirements of environmental protection.

English

English 中文简体

中文简体 русский

русский