Understanding the Function and Process of Rubber Vulcanizing Press Machines

In the rubber manufacturing industry, vulcanization is the defining process that transforms raw, elastic materials into durable, high-performance products. Central to this transformation is the Rubber Vulcanizing Press Machine, an essential piece of equipment that applies controlled heat and pressure to create stable, uniform, and resilient rubber components. From seals and gaskets to tires and industrial parts, the efficiency and precision of vulcanizing presses determine not only product quality but also overall production reliability.

The Core Function of a Rubber Vulcanizing Press Machine

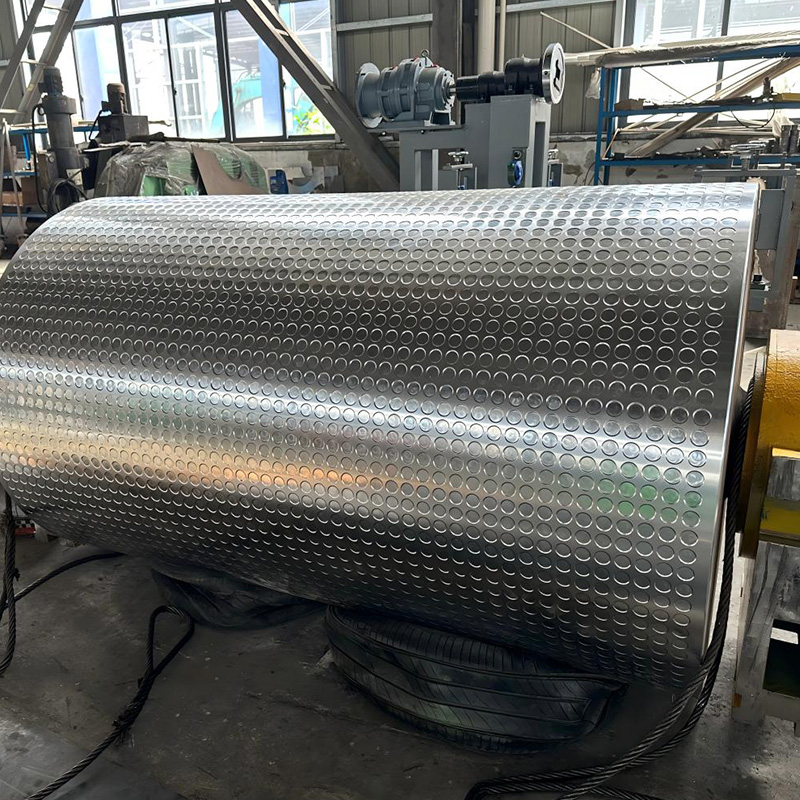

A Rubber Vulcanizing Press Machine operates by using heat and pressure to initiate a chemical reaction between rubber and vulcanizing agents such as sulfur. This reaction crosslinks the rubber molecules, improving elasticity, tensile strength, and resistance to deformation. During operation, the machine’s upper and lower platens compress the rubber compound within a mold cavity, maintaining a consistent temperature and pressure throughout the vulcanization cycle.

The process results in rubber components that exhibit improved hardness, elasticity, and resistance to aging. By controlling parameters such as temperature, pressure, and curing time, manufacturers can tailor product performance to meet specific application needs. Modern vulcanizing presses often include programmable control systems that enable precise process management, minimizing human error and ensuring consistent results across batches.

The Vulcanization Process: From Raw Compound to Finished Product

The vulcanization process typically begins with the preparation of the rubber compound, which is mixed with curing agents and additives to achieve the desired properties. The compound is then shaped and placed into a mold within the press. Once the mold is closed, the Rubber Vulcanizing Press Machine applies heat and pressure for a predetermined period, allowing the crosslinking reaction to take place.

When curing is complete, the mold opens and the product is removed for cooling and trimming. This sequence can be automated for continuous production or adjusted for customized components. With advanced Rubber Vulcanizing Press Machines, manufacturers can achieve faster curing times, reduced waste, and improved precision—all critical factors in maintaining competitiveness in today’s industrial markets.

Importance of Technology and Precision in Rubber Processing

As demand for high-quality rubber components increases across sectors such as automotive, construction, and industrial equipment, manufacturers are relying on more advanced vulcanizing technologies. Modern presses integrate digital control systems, precise temperature management, and hydraulic stability to ensure consistent vulcanization quality. Features like automated pressure compensation and mold monitoring systems help prevent under-curing or over-curing, both of which can compromise product integrity.

For specialized applications—such as high-temperature seals or vibration-damping components—precision in vulcanization parameters is essential. Advanced Rubber Vulcanizing Press Machines are designed to deliver uniform curing results, allowing manufacturers to maintain consistent mechanical performance across diverse product lines.

Anhui Sincere Machinery: Delivering Reliable Vulcanization Solutions

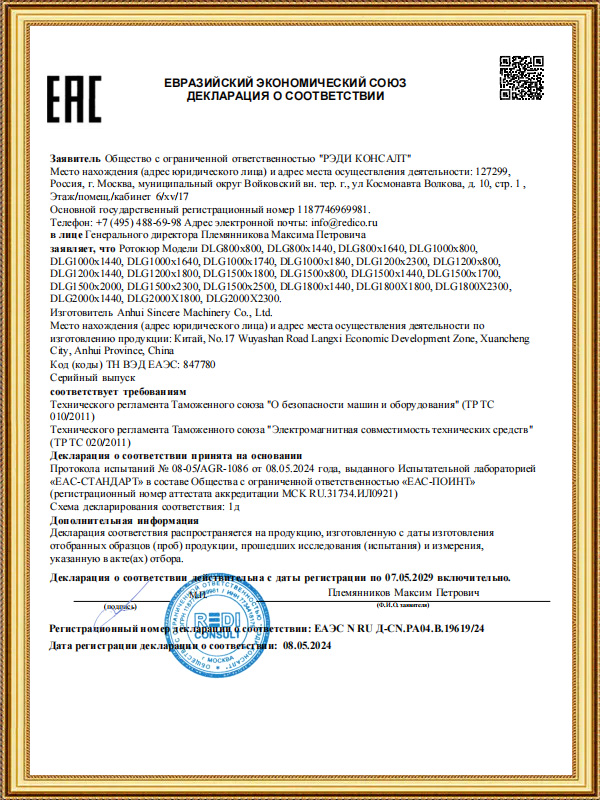

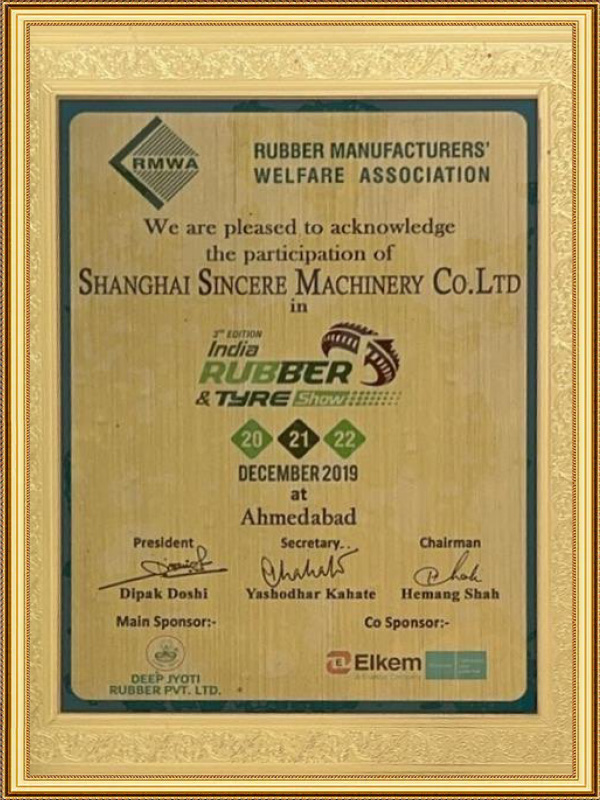

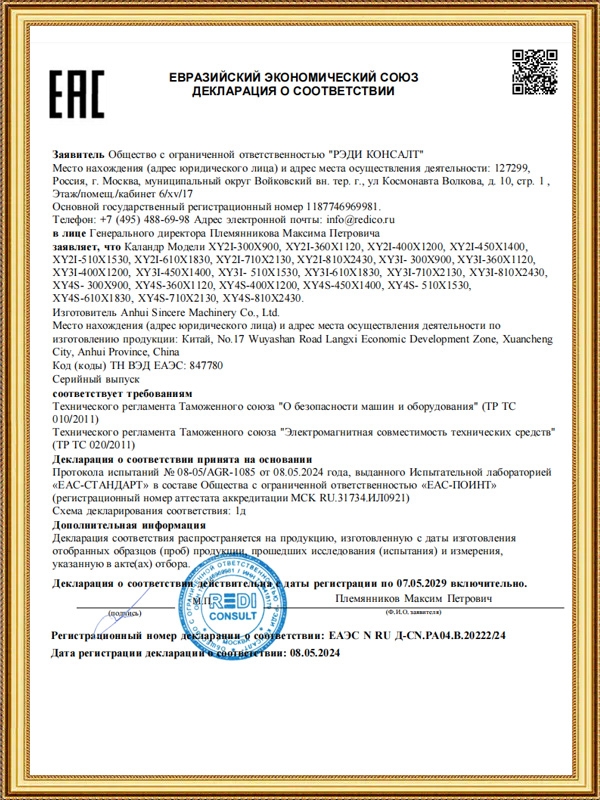

As a professional manufacturer in the rubber and plastic machinery industry, Anhui Sincere Machinery Co., Ltd. has developed a reputation for designing efficient and durable vulcanizing equipment. Founded in 2017, the company integrates research, design, manufacturing, and after-sales service, offering customers comprehensive support throughout the entire equipment lifecycle.

With a team of experienced engineers, Anhui Sincere Machinery focuses on improving process precision and energy efficiency in its Rubber Vulcanizing Press Machines. Each piece of equipment is built under strict quality control standards to ensure stable operation and long-term reliability. The company’s integrated model of industry and trade allows it to provide fast technical response and tailored solutions for clients in various sectors, from rubber sealing production to automotive component manufacturing.

Commitment to Quality, Innovation, and Service

Anhui Sincere Machinery’s approach goes beyond equipment manufacturing—it emphasizes customer success. By combining advanced mechanical design with responsive technical support, the company helps customers achieve optimized production outcomes and cost-effective operation. Their Rubber Vulcanizing Press Machines are designed not only for performance but also for ease of maintenance and adaptability to different production requirements.

Through continuous innovation and customer-centered development, Anhui Sincere Machinery continues to enhance its position as a trusted partner in the global rubber machinery market. The company’s dedication to reliable performance and professional service reflects its long-term commitment to advancing rubber processing technology and supporting sustainable industrial growth.

English

English 中文简体

中文简体 русский

русский