Enhancing Production Quality with Advanced Rubber Extruder Technology

In modern manufacturing, precision, consistency, and material performance are critical to achieving high-quality end products. The Rubber Extruder Machine has become an indispensable piece of equipment in industries that demand continuous and stable processing of rubber and silicone materials. Designed to convert raw materials into precisely shaped profiles, sealing strips, or hoses, these machines play a central role in ensuring both efficiency and product uniformity across multiple sectors, from automotive and construction to transportation and infrastructure.

The Working Principle of Rubber Extruders

A Rubber Extruder Machine operates by applying a combination of heat, pressure, and mechanical shear to process rubber or silicone compounds. The material is introduced through the feed port and conveyed forward by a rotating screw. As the screw turns, it generates frictional heat and shear that gradually plasticize the material, transforming it into a homogeneous, moldable state. Once the rubber or silicone is fully plasticized, it is forced through a specially designed die that shapes it into the desired cross-section.

The extrusion process does not end at the die. The freshly extruded product undergoes cooling, pulling, and cutting operations that define its final dimensions and surface quality. This seamless integration of mechanical and thermal control is what allows Rubber Extruders and Silicone Extruders to produce consistent, defect-free products in large volumes, greatly enhancing productivity and reducing material waste.

Versatile Applications in Industrial Production

Rubber Extruder Machines and Silicone Extruder Machine is widely used to produce sealing strips, hoses, and various profiles essential in numerous industries. In the automotive sector, extruded rubber and silicone components are used in door and window seals, ensuring effective insulation against water, air, and vibration. In the construction field, these machines produce water-stop profiles and gaskets for aluminum windows, building curtain walls, and container doors, contributing to structural durability and safety.

Beyond these core uses, the extrusion process is equally vital in marine, railway, and bridge engineering applications. High-speed rail systems and ships rely on rubber sealing profiles that maintain performance under harsh environmental conditions. The adaptability of Silicone Extruders enables manufacturers to meet specific technical requirements, such as flexibility, high temperature resistance, or weathering durability, depending on the end-use environment.

Technological Advancements Driving Quality

Modern Rubber Extruders incorporate advanced screw designs, temperature control systems, and precision dies to optimize the extrusion process. Intelligent control systems enable real-time monitoring of extrusion parameters such as temperature, pressure, and torque, ensuring consistent material flow and stable product quality. These innovations not only improve the accuracy of the extrusion process but also reduce energy consumption and maintenance costs.

For silicone-based products, Silicone Extruder Machines are equipped with temperature-resistant materials and finely tuned control systems that handle the unique viscosity and curing properties of silicone rubber. This ensures smooth processing and consistent performance, even under demanding production conditions.

Commitment to Innovation and Customer Value

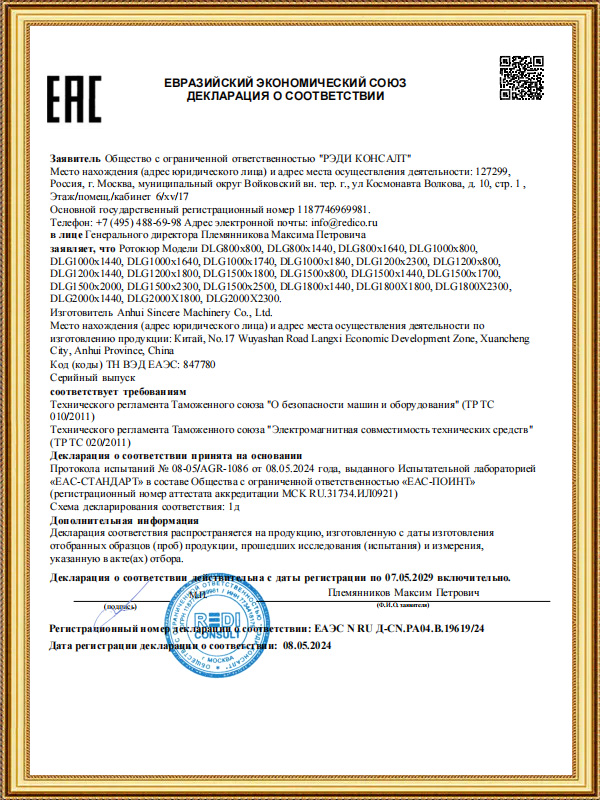

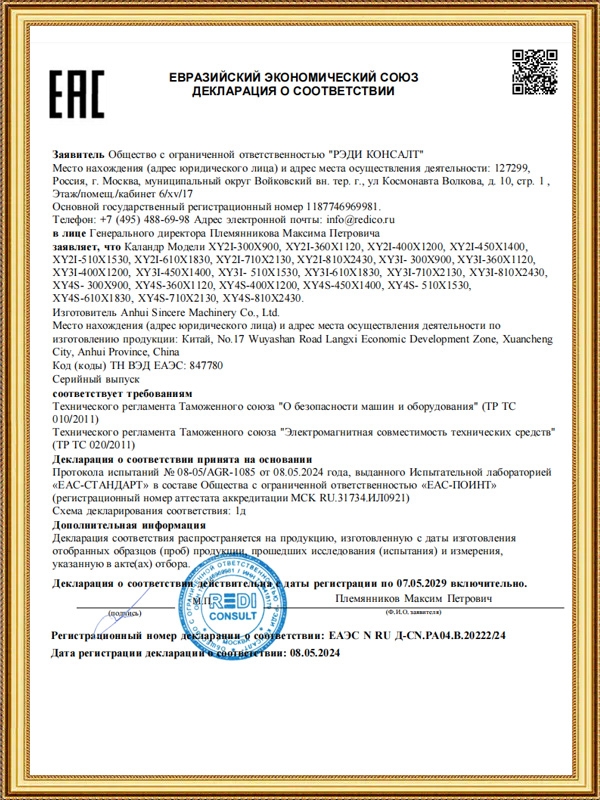

As one of the industry’s forward-looking manufacturers, Anhui Sincere Machinery Co., Ltd. has established itself as a trusted provider of rubber and plastic extrusion equipment. Founded in 2017, the company integrates R&D, manufacturing, and after-sales service to deliver comprehensive solutions tailored to customer needs. With an experienced engineering team, Anhui Sincere Machinery continuously refines machine designs to achieve better processing efficiency, energy performance, and operational reliability.

The company’s Rubber Extruder Machines and Silicone Extruder Machines are designed to meet strict quality control standards, ensuring consistent extrusion output and long-term stability. By combining advanced production technology with professional technical support, Anhui Sincere Machinery helps customers enhance their production capability while maintaining cost-effectiveness and high product quality.

Advancing Toward Smarter and More Sustainable Extrusion

As automation and digitalization reshape modern manufacturing, Rubber Extruder technology continues to evolve. Integrated monitoring systems, data-driven adjustments, and modular machine designs are enabling manufacturers to optimize production lines for different materials and applications. Anhui Sincere Machinery remains committed to this direction—offering not only durable and efficient machinery but also continuous service support to help customers stay competitive in a rapidly changing industrial landscape.

English

English 中文简体

中文简体 русский

русский