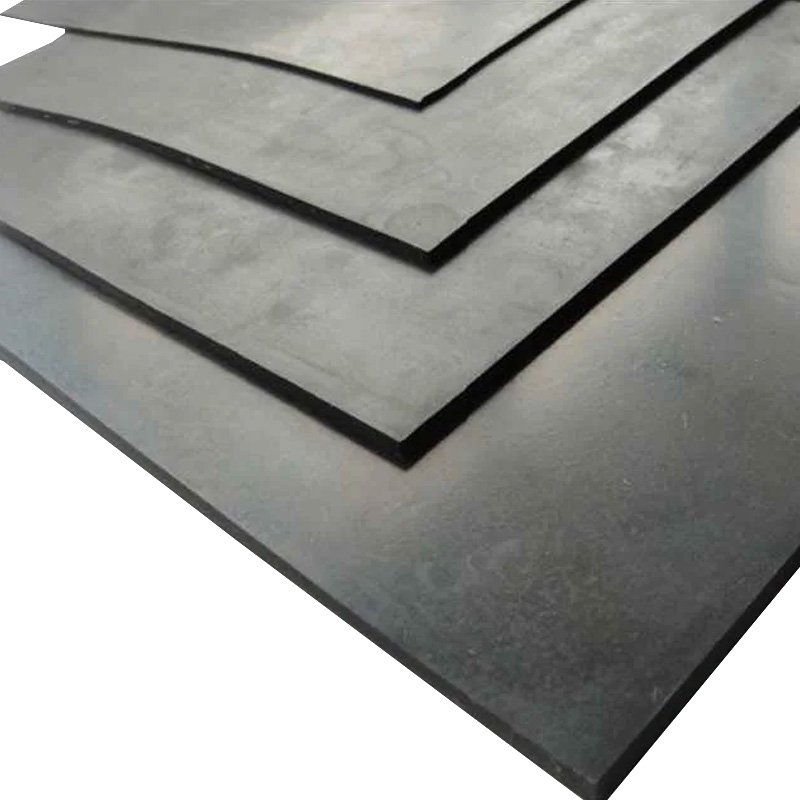

Industrial Rubber Sheet: Highly wear-resistant and high-strength industrial protective material

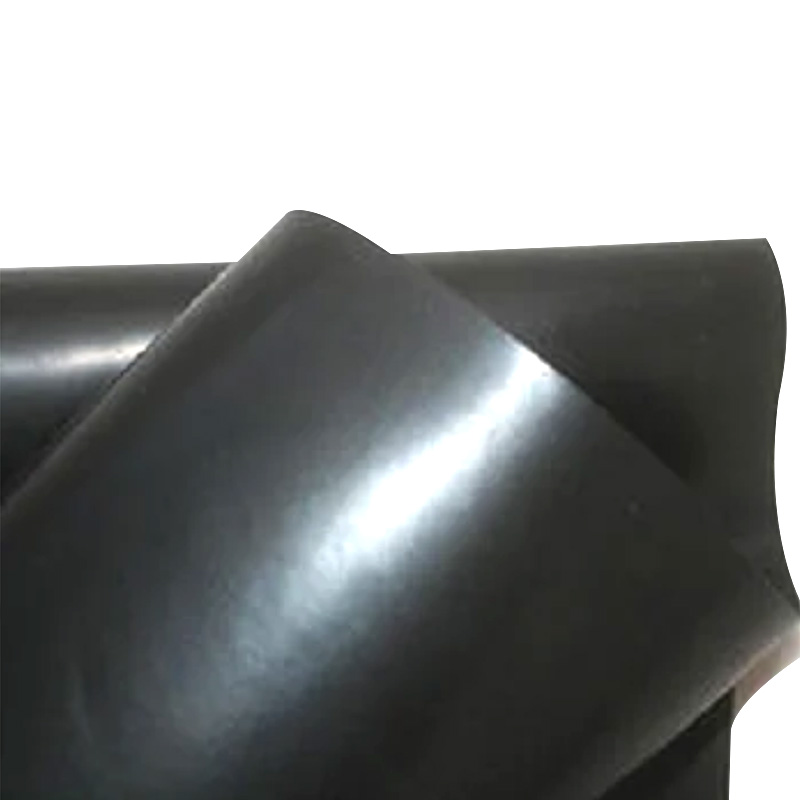

In demanding industrial environments—from mining and construction to chemical processing and heavy machinery—equipment and infrastructure are constantly exposed to abrasion, impact, corrosion, and extreme temperatures. To mitigate wear and extend service life, industries rely on a critical protective material: industrial rubber sheet. Renowned for its exceptional durability, flexibility, and resistance to mechanical and chemical stress, industrial rubber sheet serves as a frontline defense in countless applications, including conveyor linings, chute protection, gasketing, vibration damping, and floor coverings.

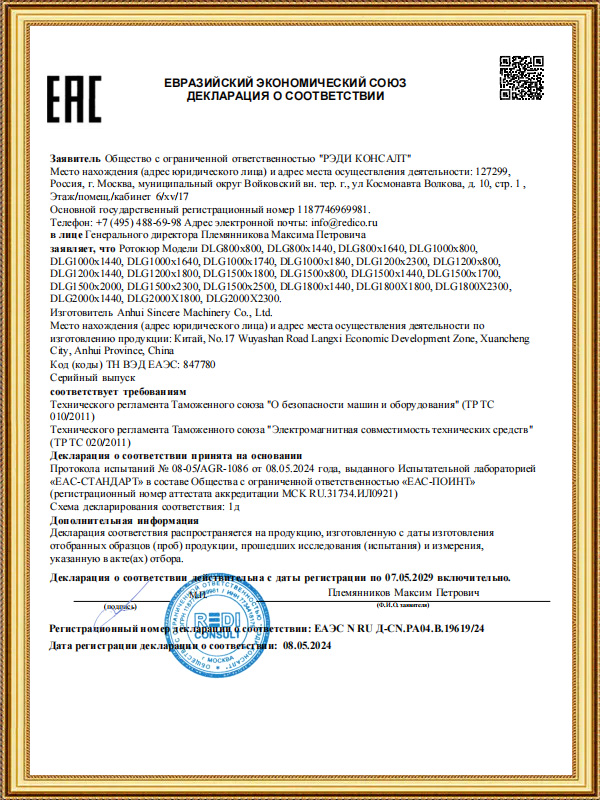

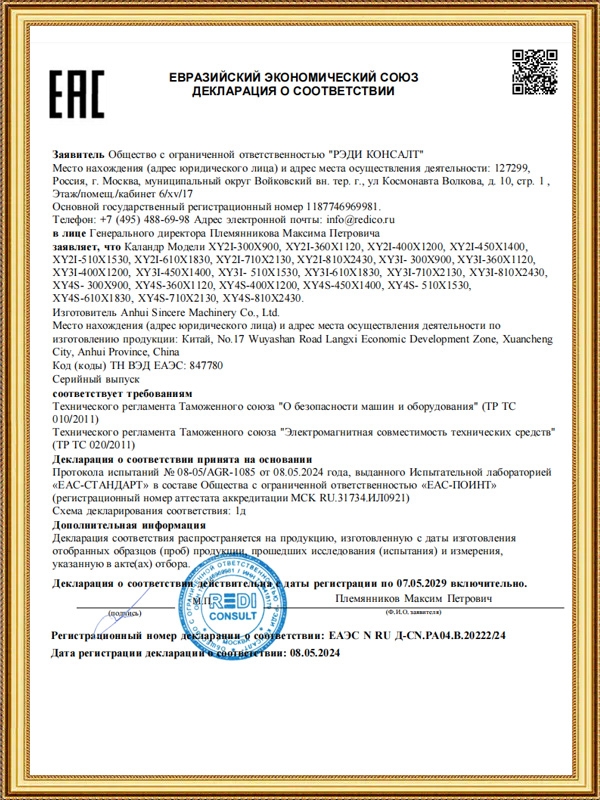

Behind the production of high-performance industrial rubber sheet lies advanced rubber processing technology—and at the heart of this innovation is Anhui Sincere Machinery Co., Ltd., a leading enterprise in the rubber and plastic machinery sector. Founded in 2017, Anhui Sincere Machinery has rapidly established itself as a trusted global supplier by integrating research and development, precision manufacturing, and comprehensive after-sales services. The company specializes in designing and producing machinery that enables efficient, consistent, and high-quality rubber sheet production, empowering manufacturers to meet stringent industrial standards.

Industrial rubber sheets are typically manufactured through calendering or extrusion processes, followed by vulcanization to achieve optimal physical properties. The performance of the final product—particularly its tensile strength, elongation, abrasion resistance, and resilience—depends heavily on the precision and reliability of the production equipment. Anhui Sincere Machinery addresses this need with a full suite of rubber sheet production solutions, including rubber calenders, two-roll mills, cooling lines, and plate vulcanizing presses, all engineered for stability, efficiency, and ease of operation.

What sets Anhui Sincere apart is its deep understanding of rubber formulation and processing dynamics. The company’s team of experienced engineers works closely with clients to recommend the most suitable machinery configuration based on raw materials (such as natural rubber, SBR, NBR, or EPDM), desired sheet thickness (ranging from 1 mm to over 50 mm), width, and performance requirements. Whether producing oil-resistant sheets for automotive gaskets or ultra-wear-resistant liners for mining conveyors, Anhui Sincere ensures that every machine is optimized for the target application.

Quality control is embedded into every stage of Anhui Sincere’s manufacturing process. From casting and machining of heavy-duty rollers to assembly of hydraulic and temperature control systems, each component undergoes rigorous inspection. The company adheres to strict international quality standards, ensuring that its rubber sheet production lines deliver uniform thickness, smooth surface finish, and consistent vulcanization—critical factors in achieving high-strength, long-lasting industrial rubber sheets.

Moreover, Anhui Sincere Machinery’s integrated “industry + trade” business model enhances its ability to provide holistic support. Beyond supplying equipment, the company offers professional purchasing advice, layout planning for production lines, on-site installation, operator training, and lifetime technical assistance. This end-to-end service approach minimizes setup time, reduces operational risks, and accelerates return on investment for clients—especially those entering the rubber sheet market or upgrading legacy systems.

The demand for industrial rubber sheets continues to grow globally, driven by infrastructure development, industrial automation, and the need for sustainable, long-life materials that reduce maintenance costs and downtime. In response, Anhui Sincere is also exploring innovations such as energy-efficient heating systems, digital monitoring platforms, and compatibility with recycled or eco-friendly rubber compounds—aligning its technology with the future of green manufacturing.

Clients across Asia, Africa, the Middle East, and South America have already benefited from Anhui Sincere’s reliable machinery and responsive support. One manufacturer in Southeast Asia reported a 30% increase in production efficiency after replacing manual calendering with Anhui Sincere’s automated rubber sheet line, while a European client praised the company’s rapid spare parts delivery and remote troubleshooting capabilities.

In summary, industrial rubber sheet is far more than a simple protective layer—it is a high-performance engineered material essential to modern industry. And the quality of that material begins with the machinery that produces it. With its commitment to innovation, quality, and customer success, Anhui Sincere Machinery Co., Ltd. stands as a strategic partner for rubber product manufacturers worldwide. By delivering cost-effective, high-performance equipment backed by strong service support, the company enables its clients to produce industrial rubber sheets that meet the toughest challenges—today and tomorrow.

English

English 中文简体

中文简体 русский

русский